Home

Precision Glass Products Co. brings design engineers, scientists and researchers together to ensure high quality precision manufactured products.

Precision glass Products Co. (founded, 1955) has over 60 years experience manufacturing special & custom precision products from various types of glass, fused quartz, fused silica, aluminum, ferrite, Zerodur ® and other ceramics.

Grinding & Polishing

Glass & Quartz

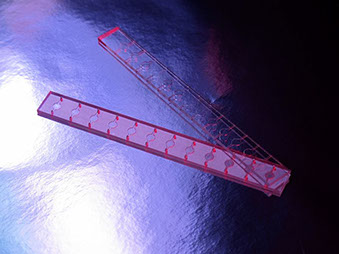

Precision Glass Products can grind a variety of glass and quartz materials to meet your specific size, shape, and finishing needs. Our process uses different types of grinding, such as jig and spherical grinding, on materials including black quartz, optical glass, and fused silica.

We can machine parts as large as 12” in diameter with tight tolerances. We use OD/ID grinders, surface grinders, jig grinders, and lapping and polishing machines.

We have produced custom glass parts for customers in a variety of industries including electronics, medical, and government.

Thermal Forming

Scientific Glass Blowing

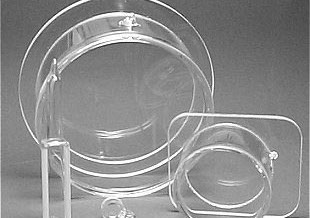

Precision Glass Products has the capability to provide quartz or borosilicate glass cells that contain pure gases, or mixtures of pure gases, as specified by the user. Such cells are used as calibration standards or for other applications where a repeatable spectrum is desirable. The cell is evacuated down to 10 microns of pressure and then purged with the gas or gas mixture. The cell is then permanently sealed by fusing closed the filling aperture.

The pressure of gas in the cell can generally be controlled very accurately from about 750 torr (.985 atmosphere) down to 50 to 60 Pa (about 0.5 torr). Exact pressures and specific repeatability are dependent upon the specific gas or gas mixture required. Once sealed closed, the lifetime of the cell is only limited by the permeability of the glass or quartz to the particular gases involved.

Contact our technical sales department with your requirements for a prompt quotation.

Contact Us

Please use one of the following methods to contact a representative from Precision Glass Products.

Special Features

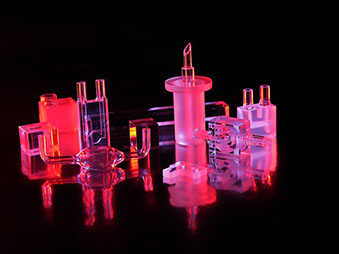

This photograph of an experimental quartz chamber, clearly demonstrates Precision Glass Products' unique manufacturing capabilities. This remarkable device, produced in small quantities under contract to NASA, requires a high level of expertise in several quartz (or glass) fabrication technologies:

This photograph of an experimental quartz chamber, clearly demonstrates Precision Glass Products' unique manufacturing capabilities. This remarkable device, produced in small quantities under contract to NASA, requires a high level of expertise in several quartz (or glass) fabrication technologies:Precision Grinding of part geometry to ±0.0001

Assembly of individual quartz parts by fusion bonding with no loss of accuracy. Hermetic encapsulation of a metal core within a quartz cylinder. The quartz chamber was produced for microgravity research experiments being conducted by NASA. Dubbed the Isothermal Dendritic Growth Experiment, or IDGE, these chambers are to be used to observe and record dendritic growth in materials under weightless conditions (aboard the space shuttle.) More information concerning IDGE can be obtained at http://www.rpi.edu/locker/56/000756. An E-mail address is also available at IDGE@rpi.edu.

The chamber, constructed from 15 separately generated synthetic quartz components (and one metal piece), has many unusual features. The large main housing is precision ground from a single piece of high grade material and then optically polished on several of its exterior as well as interior surfaces. Four holes are bored through the housing and honed to a high degree of accuracy and finish. These are used to provide access to the interior for the following attachments:

- Thermistor - A closed tube, open to the outside only, accepts a thermistor probe used to monitor the temperature of materials inside the chamber.

- Stinger - Another precision tube which has one end finely ground to a sharp angled point. This tube is closed to the outside. Dendritic growth begins at the tip of the stinger tube.

- Fill Tube - A quartz tube bent to a 90 degree angle and constricted to an hour-glass shape at one point. This tube is used to evacuate the chanber and to fill it with test material. It is then thermally closed off at the point of the constriction.

- Pump - The pump is by far the most complex of the four attachments and is actually an operating piston and cylinder manufactured from 6 separate pieces of synthetic quartz. A metal core is encapsulated under a vacuum process within the quartz and this, after precision cylindrical grinding and lapping to an 8 microinch finish, becomes the piston. The metal core is required so that the pump can be electromagnetically driven. The cylinder for the piston is honed on its internal diameter to produce a uniform gap around the piston. Gaps from 0.0004 to 0.0012 inches ±0.0002 inches have been manufactured. Finally a fill tube and cylinder head are thermally bonded to one open end of the cylinder.

The four attachments are then thermally bonded to the main housing of the chamber. These bonds are accomplished under rigidly controlled conditions of heat and pressure and result in virtually no loss of optical properties or deformation of part geometry. After fine annealing, the final product is essentially a single piece of quartz. Optical windows are then frit bonded to the remaining open sides of the chamber.

For more information, please do not hesitate to contact Precision Glass Products Company at our phone, fax, or e-mail sites. Our technicians are always available to discuss your requirements.

Virtual Tour

1 - 22

<

>

Precision Glass Products Company

143 Montgomery Ave, Oreland PA, 19075

Phone: 215-885-0145 | Fax: 215-885-2792 | sales@pgpcompany.com